Our processes

New technologies are extremely avid in all kinds of metals. The by-products generated by the metal extraction, as well as the recycling of end-of-life technologies generate new and increasingly complex waste.

New technologies are extremely avid in all kinds of metals. The by-products generated by the metal extraction, as well as the recycling of end-of-life technologies generate new and increasingly complex waste.

These urban mines offer a considerable source of raw material supply, an alternative to the extraction of new natural resources. Recycling these secondary materials is now essential to reduce industrial dependence on complex supply chains. The EU is well aware of this situation and has set up the “Raw Materials” initiative as part of a European geostrategic plan. It aims at ensuring the security of supply, the sustainability and the affordable cost of these raw materials. This measure aims to encourage recycling, a concept JGI-HYDROMETAL fully supports.

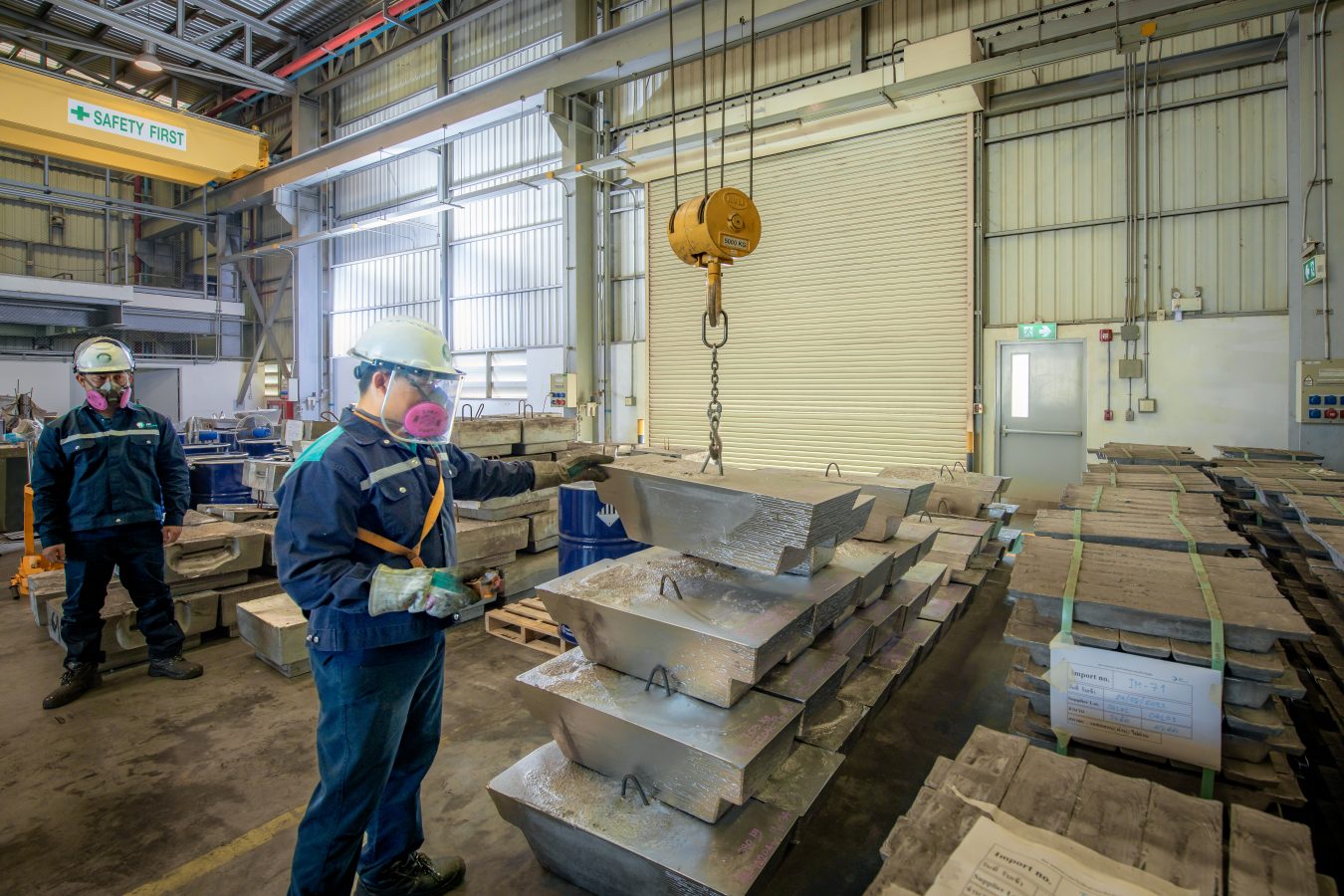

Through its focus on the recovery of secondary materials, JGI-HYDROMETAL is a major player in the recycling challenge and in the circular economy. Over time, JGI-HYDROMETAL has expanded its technical knowledge in the latest technologies and benefits from world-renowned expertise.

By combining our expertise in hydrometallurgy (metal treatment in an aqueous medium) and in pyrometallurgy (thermal treatment), we use this complimentary to “close the loop” and deal with the complexity of flows.

Our methods can process materials from different sources and different aspects: concentrates, co-products, by-products, slag, complex secondary materials, residues, flue dust, used catalysts, alloys, dross, waste, etc. These materials are transformed into sulphates, salts, mattes, hydroxides, oxides, carbonates, or refined metals. Once cleared of their impurities, the purified metals serve as raw materials that can be used by other metallurgical plants, in the chemical industry or other specific phytosanitary, electronic, glass applications, etc.